Electrostatic Precipitator Design Calculator Air Pollution Control. Mitsubishi Power contributes to air pollution control at thermal power plants steel plants and various.

Moving Electrode Type ESP.

. This precipitation process is now widely used in apartments offices and hospitals as well as. Particles passing through the precipitator are given a negative electrical charge by being forced to pass through a region called a corona. Dilip Kumar Deepak Kumar in Sustainable Management of Coal Preparation 2018.

Optimizing design values with a calculator is difficult and time consuming. For several of the industries the available infor-mation is somewhat incomplete particularly in the. Different electrical potentials ϕ 15 30 kV are applied to the three discharge electrodes wires.

0 0 0. Gas flow rate Q 0 0. Calculations have been done with a calculator and written by hand with pen or pencil.

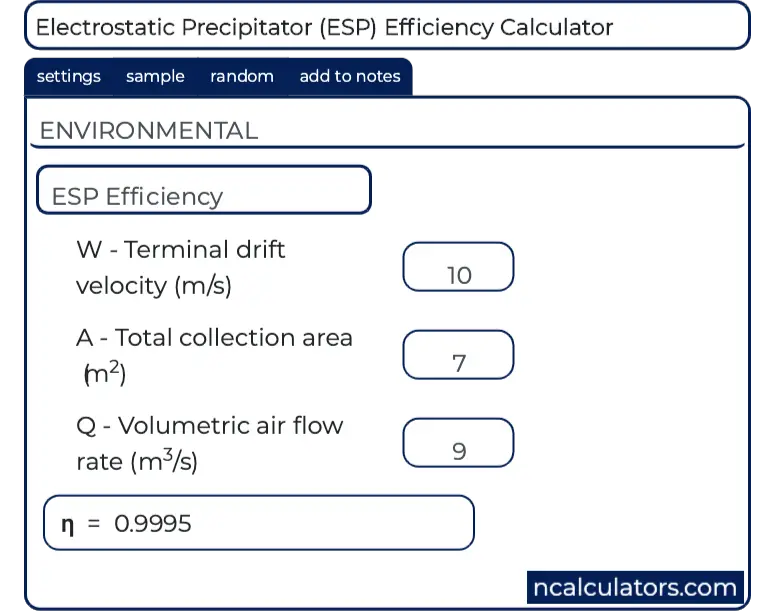

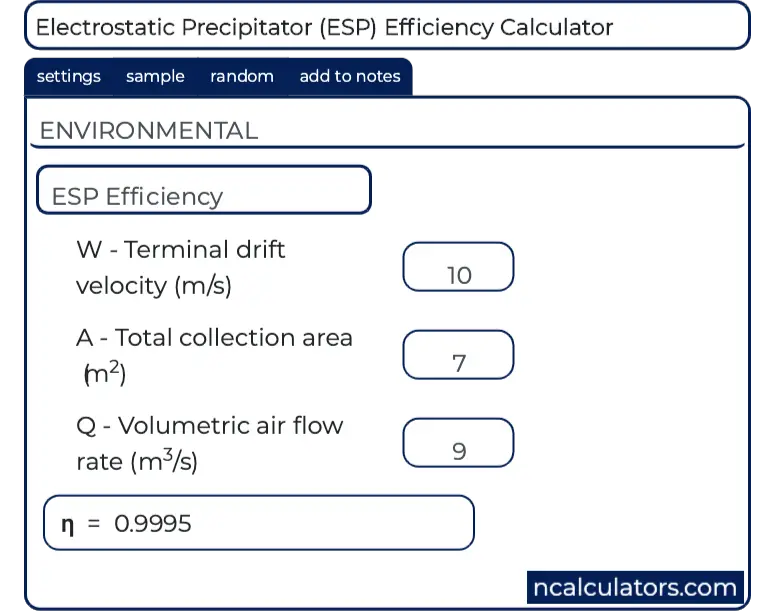

Electrodes collecting area A meter2 particle drift velocity V metersecond gas flow rate Q meter3second. Particle drift velocityV d 0 0. Electrodes collecting area A particle drift velocityV d collection efficiency R unitless.

DISCHARGE ELECTRODE HIGH VOLTAGE SUPPORT FRAME The power supplies for the ESP con-vert the industrial AC voltage 220-480 V to pulsating DC voltage in the range of 20000-100000 V as needed. Electrostatic precipitator V-I character Function. A 37 m2.

0298 303 1 r E ρ ρ 1. Excel and other spread sheets are used to calculate and optimize dust collection equipment parameters. Calculation of electric field strength distributions for new electrostatic precipitator discharge electrode designs.

E elementary charge electric charge carried by a single proton or the negation of the electric charge carried by a single electron 16 x 10-19 C Q flow rate 73m3 s V 𝐼 𝐴𝑒. The charged particles are then attracted to collector plates carrying the opposite charge. OSTIGOV Journal Article.

And design of the tri-electrode this paper puts forward that V-I characteristic curve of common wire-plate type electrostatic precipitator can be expressed as IaVb model and provide the corresponding value of b. The collected particles may be removed from the collector plates as dry material dry ESPs. Well design data and deviation survey 2.

Collection efficiency R 0 0. Please provide well completion diagram 4. Electric Field m2 Diameterm Lengthm Operating.

PRINCIPLES OF ELECTROSTATIC PRECIPITATOR Electrostatic precipitation is a method of dust collection that uses. Quite often it is impossible to read and check these documents. While some users rely on the precipitator manufacturer to determine proper sizing and design parameters others choose to either take a more active role in this process or hire.

The results indicate that R-square is a less than 05. 1mgm 3 N. The supply consists of a step-up trans-.

_____ or attach Deviation survey Table No4 Deviation survey Well construction Azimuth. Electrostatic precipitators ESP collect dust in the flue gas produced by boiler etc. Solving for electrodes collecting area.

ESPs are particulate control devices that use electrical forces to move particles from the air stream to the collection plates. Electrodes collecting area A 0 0. Capacitym 3 h Qty of Cellular.

Technical parameters of TNJD-II High Voltage Wet Electrostatic Precipitator. Gas flow rate is a fundamental factor in the design and performance of electrostatic precipitator. The calculation of the parameters of the electrostatic precipitator starts with the selection of the corona discharge Fig.

The quantity of combustion gas produced in the boiler depends on the composition and amount of coal burned the excess air used for combustion and the air in-leakage through the furnace flues and air-preheaters. Industrial Gas Cleaning Institute. Used to determine the collection efficiency of the precipitator under ideal conditions.

Electrostatic precipitator operations found in the United States and 2 for these industries most of the required data for the efficiency calculations via the Theodore model are available in the literature4 These data are listed in Table I. Plate Area 3600 m2 x 85 m 75 m 4080 m2 Plate Area of Section Sectional area 40803 1360 m2 Gas Velocity Volume flow width x height 119 m3s 788 m x 85 m 159 ms SCA Total area volume flow rate 4080 m2 119 mVs 343 m2m3s sm SCA of Section Total SCA. This electrical equipment was first introduced by DrFG.

10mgm 3 N. Gas flow rate Q particle drift velocityV d collection efficiency R unitless. The calculations are carried out for a wire-to-plate spacing H 0175 m length of ESPL 2210mandwire-to-wirespacingof0725mwithradiusofwireRwire 10 mm and inlet air-particle velocity of 12 ms.

The simplest form of the equation is given below. Casing size and weight inchppf. The obtained results showed that the adopted design of the electrostatic precipitator enables the reduction of dust emissions generated in the combustion of solid fuels in households at relatively.

Design Of Electrostatic Precipitator for smoke precipitator. It is seen that the particle. 2ris016 ElctrostateProcptator Design Equations Formulas Calculator - Colloct Electrostatic Precipitator Design Calculator Air Pollution Control Solving for collection efficiency estimate oa Reivel Inputs.

Achieving optimum electrostatic precipitator performance requires proper sizing of the electrostatic precipitator in addition to optimizing precipitator efficiency. An electrostatic precipitator ESP removes particles from a gas stream by using electrical energy to charge particles either positively or negatively. Solving for gas flow rate.

Lesson 4 4-2 20-298 Introduction As discussed in Lessons 2 and 3 finalizing the design of an electrostatic precipitator and its components involves consideration of many factors. η collection efficiency of the precipitator e base of natural logarithm 2718 w migration velocity cms ftsec A the effective collecting plate area of the precipitator m2 ft2. Electrostatic Precipitator Design Calculator Air Pollution Control.

Electrostatic precipitation is the most Preferable way to remove solid Particle pollutants like dust and smoke or liquid mist oil contained in the gas injected into the environment. The intensity of electrostatic field at which the corona discharge occurs is called critical and can be calculated with the formula 1. Cottel in 1906 and was first economically used in 1937 for removal of dust and ash particles with the exhaust gases of thermal power plants.

Sectional Area of. The volume flow rate through. Particle drift velocityV d 0 0.

V 006 𝐴 61016 337 2161019𝐶 168 ms Collection efficiency. Using the data from ESP Design for SAMPLE the following calculations are made.

Electrostatic Precipitator Efficiency Calculator

Electrostatic Precipitator Design

Electrostatic Precipitator Efficiency Calculator

Typical Electrostatic Precipitator Configuration Download Scientific Diagram

0 komentar

Posting Komentar